In-Plant Transfer

Convey Anywhere – Noise Control – Superior Dust Control

Pneumatic conveying is ideal for in-plant transfer due to flexibility in routing – we can convey material to places others can’t. It is also ideally suited for dust control because it’s a closed system with few ventilation points.

Routing is very flexible and less moving parts means less breakdowns. A wide variety of dry bulk materials can be conveyed this way with lower maintenance, power, and labor costs.

For compliance purposes, we can attenuate noise created by indoor blower packages by design or by including a sound enclosure.

There are many advantages to pneumatic transfer compared to mechanical conveying:

- Closed system conveying reduces cross-contamination

- Routing flexibility

- Easy dust control

- Can have several pick-up points and routes controlled with valves

- Wide variety of materials can be conveyed

- Ease of automation and control

We have designed systems for thousands of materials. Call an experienced engineer at US Systems, we’ll answer your questions and solve your problems. It’s what we do!

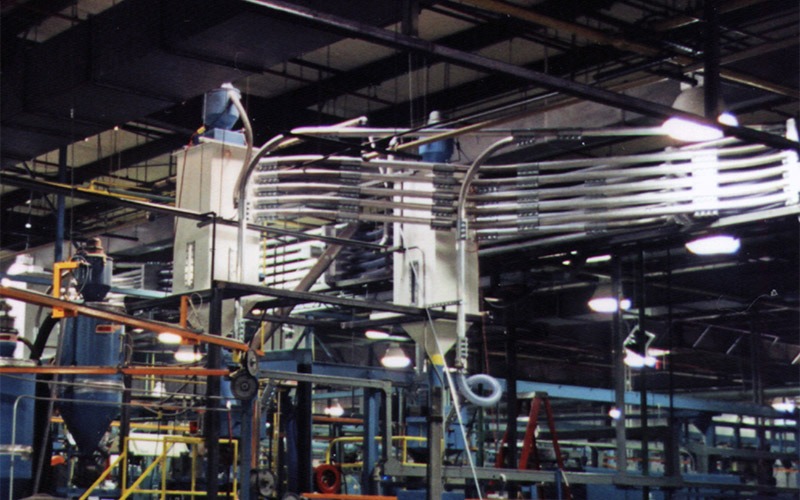

These photos illustrate the fact that these are closed systems that reduce cross-contamination, allow for easy dust control, and easily have several pick-up points and routes controlled with valves.

Our Pneumatic Conveying Solution Eliminates:

- Blow-by Air

- Worn Shaft Seals

- Bent Rotors

- Holes in Elbows

- Wasted Horsepower and Energy

- Worn Out Housings

- Chain Drive Maintenance

- Valves with Inherent Leaks

High Rates

These high-rate systems employ either diesel or electric driven portable units that can range from 10 to 200 horsepower and can move material at a rate of one to one-hundred ton per hour.

Supporting Systems:

To match the environment of our customers operations, US Systems Pot, boosters, and supporting systems are designed to be especially rugged. Unlike our competitors, we custom-design our systems to fit your existing systems, not the other way around.

Each US Systems Pot features:

- Stainless, Aluminum, or Carbon Steel Construction

- Visual Inspection Sight Glasses

- User-Friendly Access/Clean-Out Ports

- Manual or Automatic Controls of Pneumatic and Electrical Functions

- Premium Components Designed to Last

- We Offer 12VDC, Pneumatic, or 120VAC Options for Controls